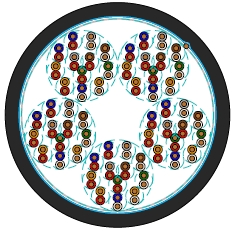

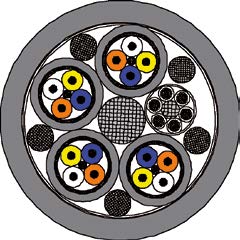

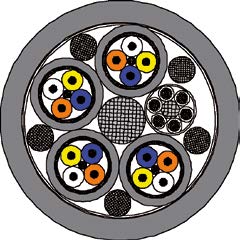

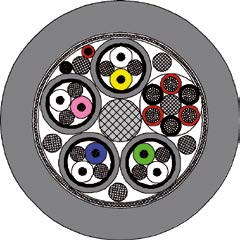

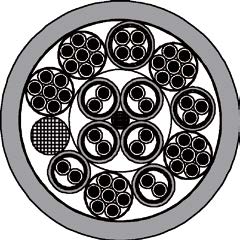

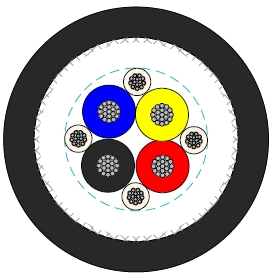

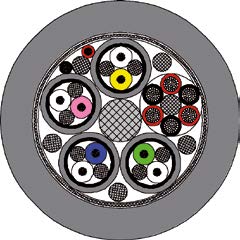

-Used as power and control cable for protected installations inside and outside of rail and transport vehicles, where handling and installation cost are an important factor.

-Used in control, auxillary and main circuit wiring such as cable harnesses, switchboards and control panels, driver desks etc.

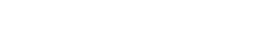

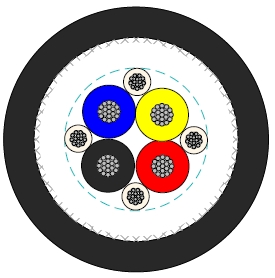

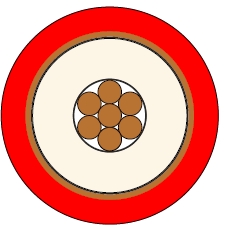

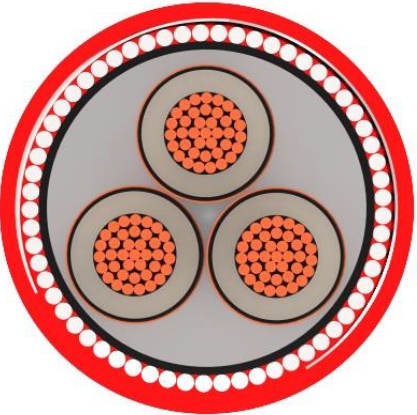

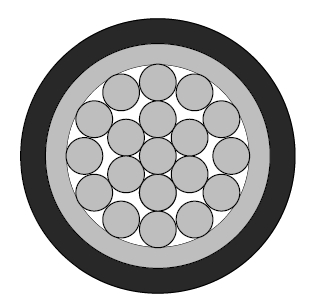

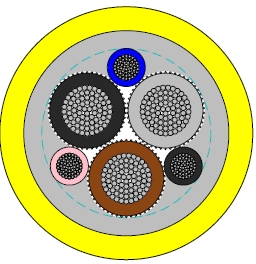

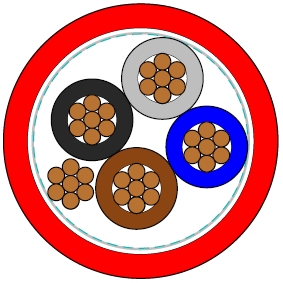

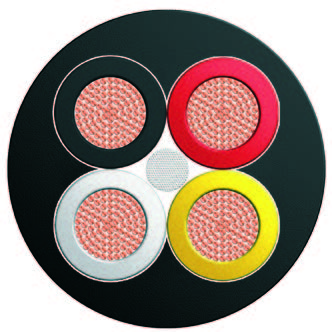

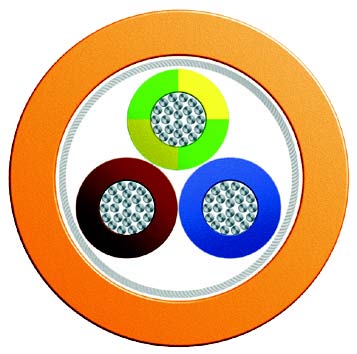

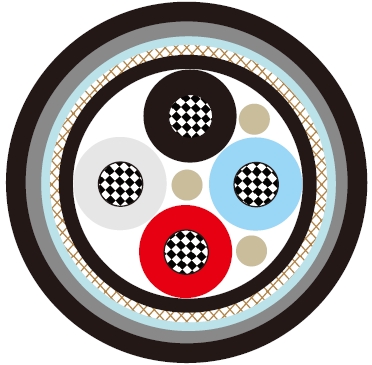

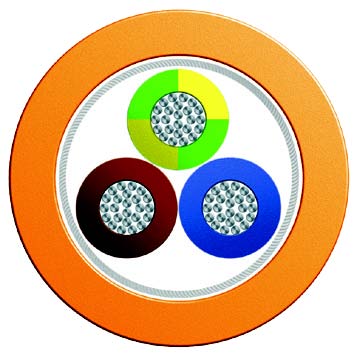

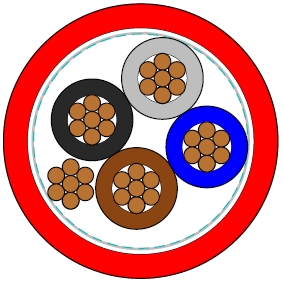

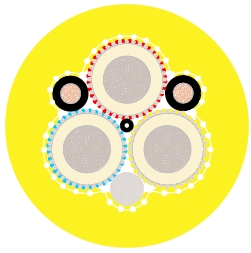

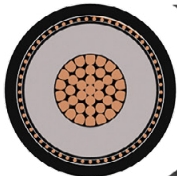

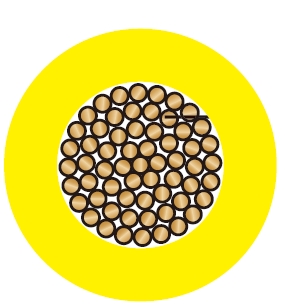

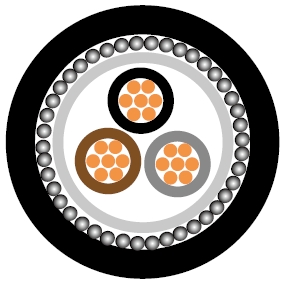

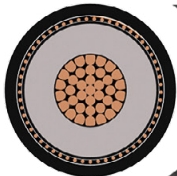

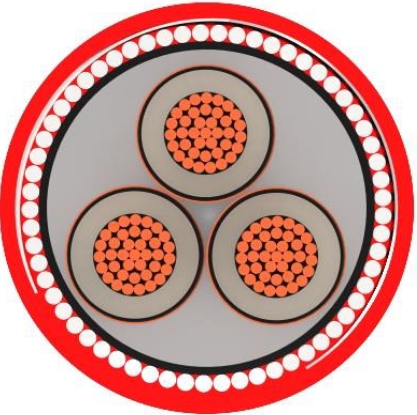

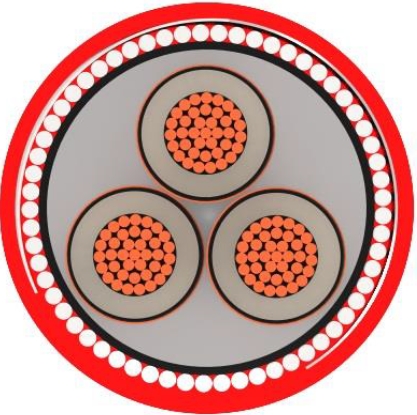

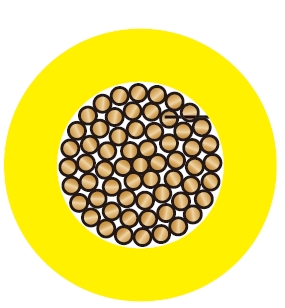

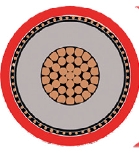

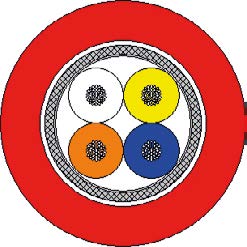

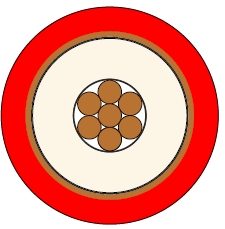

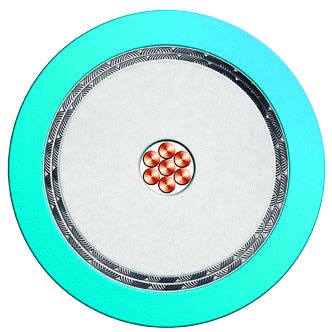

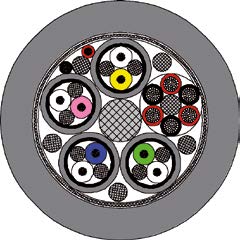

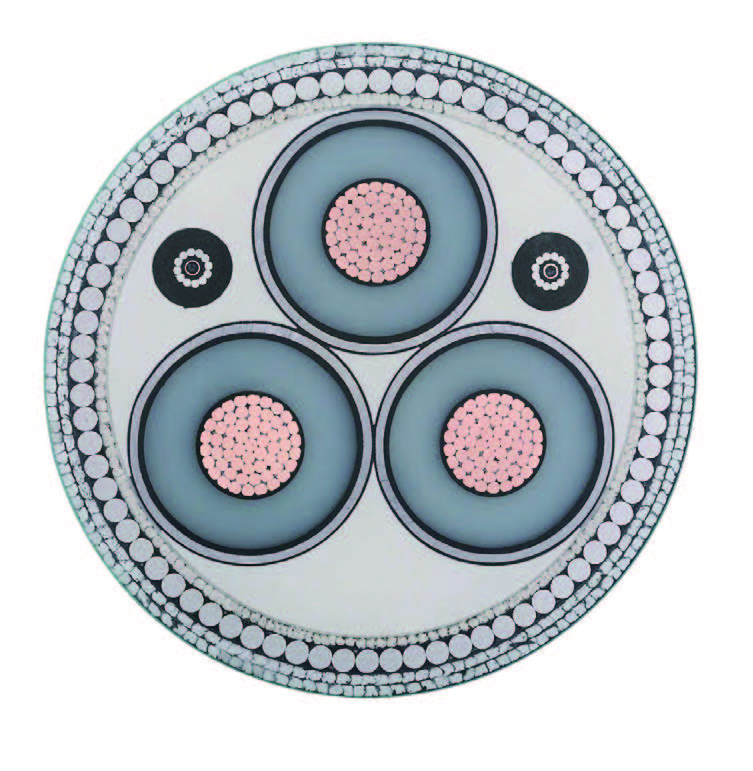

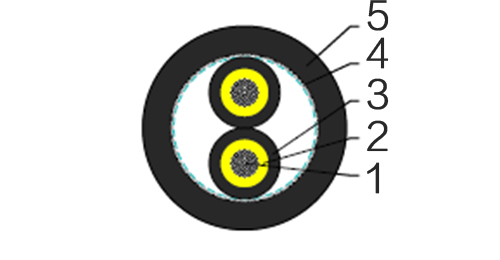

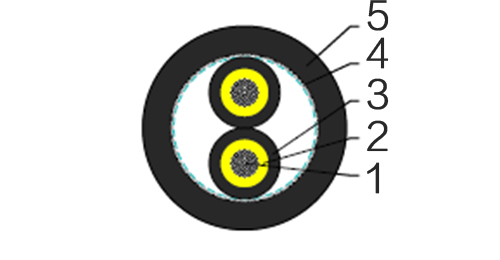

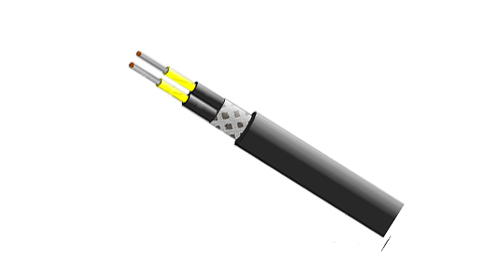

| Conductor | Flexible tinned annealed copper wires, stranded as per HD 383 (IEC 60228) class 5 |

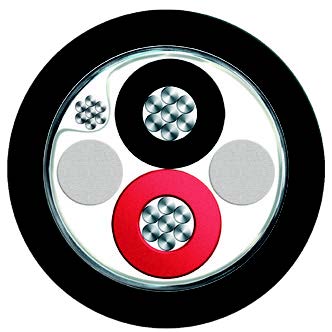

| Insulation | Mica tape+LSZH elastomeric compound as defined in EN 50264-1 (EI 101 to EI 105) |

| Overal screen | Tinned annealed copper wires |

| Outer sheath | LSZH elastomeric compound as defined in EN 50264-1 (EM 101 to EM 104) |

| Nominal Voltage | 300/500 V or 0.6/1 kV |

| Maximum Conductor Temperature | 90°C ( fixed installation ) |

| Minimum Permissible Ambient Temperature | -25°C/-40°C ( fixed installation ) |

| Bending Radius | 10 x Overall Diameter |

| EN 60684-2 | No fluorine |

| EN 50305; EN 60811-2-1 | Resistance to mineral oil & fuel oil, acid & alkali |

| EN 50305 | Resistance to ozone |

| EN 50306-2 | Hazard levels HL1, HL2, HL3 |

| DIN 5510-2 | Protection level 1/2/3/4 |

| BS 6853 | Interior use 1a, 1b, II; Exterior use 1a, 1b, II |

| NF F 16-101 | F0 |

| EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2) | Vertical flame propogation for a single insulated wire or cable |

| EN 50266-2-4 + EN 50305; IEC 60332-3-24; NF C 32-070 2.2 (C1); VDE 0472 Teil 804 | Vertical flame spread of vertically mounted bunched wires or cables |

| EN 50268-2; IEC 61034-2; NF C 32-073 ; NF C 20-902; NF F 16 101; VDE 0472 Teil 816 | Low Smoke Emission |

| EN 50267-2-1; IEC 60754-1; NF C 32-074; NF C 20-454; VDE 0472 Teil 815 | Halogen Free |

EN 50267-2-2/3; IEC 60754-2; NF C 32-074; NF C 20-453; VDE 0472 Teil 813 | Low Corrosivity (Acidity & Conductivity) |

| EN 50305; NF X 70-100; NF F 63 808; TM1-04; BS6853 | Low Toxicity |

| NF F 63 808; BS6853; NF F 16 101 | Smoke index |

| IEC60331-21 | The circuit integrity test under fire of cables rated 0.6/1.0kV and below |

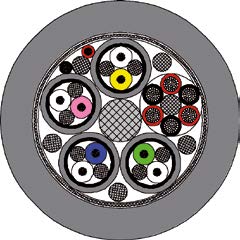

| Number And Nominal Cross-Sectional Area(a) | Conductor Diameter (b) | Min. Mean Thickness of Insulation | Diameter of Core(b) | Min Wire Diameter of Screen | Min. Mean Thickness of Sheath | Overall Diameter | Weight | Maximum Conductor Resistance | Insulation Resistance | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EI 105 | EI 101- EI 104 | |||||||||||

| Min | Max | Min | Max | 20℃ | 20℃ | 20℃ | ||||||

| n x mm2 | mm | mm | mm | mm | mm | mm | mm | mm | kg/km | Ω/km | MΩ x km | MΩ x km |

| 2x1 | 0.6 | 2.7 | 3.1 | 0.16 | 1.4 | 8.3 | 9.8 | 129 | 20.0 | 140 | 70 | |

| 4x1 | 0.6 | 2.7 | 3.1 | 0.16 | 1.4 | 9.2 | 10.9 | 188 | 20.0 | 140 | 70 | |

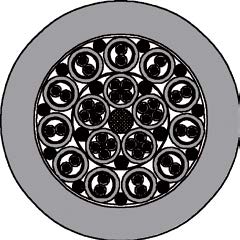

| 7x1 | 0.6 | 2.7 | 3.1 | 0.16 | 1.4 | 10.6 | 12.5 | 275 | 20.0 | 140 | 70 | |

| 9x1 | 0.6 | 2.7 | 3.1 | 0.21 | 1.4 | 12.7 | 14.9 | 360 | 20.0 | 140 | 70 | |

| 12x1 | 1.25 | 0.6 | 2.7 | 3.1 | 0.21 | 1.4 | 13.5 | 15.9 | 445 | 20.0 | 140 | 70 |

| 19x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.5 | 15.9 | 18.7 | 665 | 20.0 | 140 | 70 | |

| 24x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.6 | 18.3 | 21.5 | 832 | 20.0 | 140 | 70 | |

| 32x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.6 | 19.9 | 23.4 | 1043 | 20.0 | 140 | 70 | |

| 37x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.7 | 20.9 | 24.5 | 1181 | 20.0 | 140 | 70 | |

| 40x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.7 | 21.6 | 25.4 | 1263 | 20.0 | 140 | 70 | |

| 4x1.5 | 1.5 | 0.7 | 3.0 | 3.5 | 0.16 | 1.4 | 10.3 | 12.1 | 244 | 13.7 | 120 | 60 |

| 7x1.5 | 0.7 | 3.0 | 3.5 | 0.21 | 1.4 | 12.1 | 14.3 | 380 | 13.7 | 120 | 60 | |

| 9x1.5 | 0.7 | 3.0 | 3.5 | 0.21 | 1.4 | 14.3 | 16.8 | 476 | 13.7 | 120 | 60 | |

| 12x1.5 | 0.7 | 3.0 | 3.5 | 0.21 | 1.5 | 16.0 | 18.8 | 604 | 13.7 | 120 | 60 | |

| 19x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.5 | 18.0 | 21.1 | 895 | 13.7 | 120 | 60 | |

| 24x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.6 | 20.9 | 24.5 | 1120 | 13.7 | 120 | 60 | |

| 32x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.7 | 22.9 | 26.9 | 1430 | 13.7 | 120 | 60 | |

| 37x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.7 | 23.8 | 27.9 | 1610 | 13.7 | 120 | 60 | |

| 4x2.5 | 1.95 | 0.8 | 3.6 | 4.2 | 0.21 | 1.4 | 12.0 | 14.2 | 330 | 8.21 | 90 | 45 |

| 7x2.5 | 0.8 | 3.6 | 4.2 | 0.21 | 1.4 | 13.9 | 16.4 | 500 | 8.21 | 90 | 45 | |

| 9x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.5 | 17.0 | 20.0 | 670 | 8.21 | 90 | 45 | |

| 12x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.5 | 18.2 | 21.4 | 830 | 8.21 | 90 | 45 | |

| 19x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.6 | 21.3 | 24.9 | 1200 | 8.21 | 90 | 45 | |

| 24x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.8 | 24.9 | 28.9 | 1560 | 8.21 | 90 | 45 | |

(a) = One earth conductor (green/yellow) can be included upon request

(b) = For information,indicative only

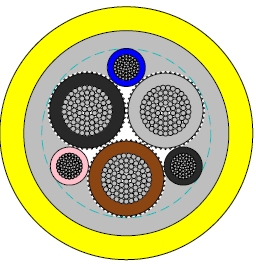

| Number And Nominal Cross-Sectional Area(a) | Conductor Diameter (b) | Min. Mean Thickness of Insulation | Diameter of Core(b) | Min Wire Diameter of Screen | Min. Mean Thickness of Sheath | Overall Diameter | Weight | Maximum Conductor Resistance | Insulation Resistance | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EI 105 | EI 101- EI 104 | |||||||||||

| Min | Max | Min | Max | 20℃ | 20℃ | 20℃ | ||||||

| mm2 | mm | mm | mm | mm | mm | mm | mm | mm | kg/km | Ω/km | MΩ x km | MΩ x km |

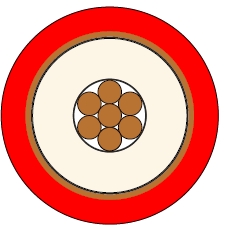

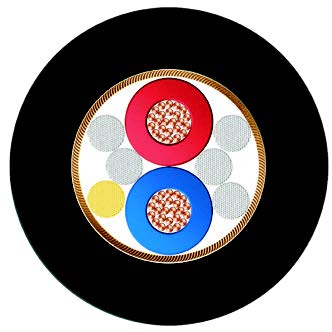

| TWO CORES | ||||||||||||

| 1.5 | 1.5 | 0.8 | 3.3 | 3.8 | 0.16 | 1.4 | 9.5 | 11.2 | 166 | 13.7 | 150 | 75 |

| 2.5 | 1.95 | 0.8 | 3.7 | 4.2 | 0.16 | 1.4 | 10.4 | 12.2 | 207 | 8.21 | 130 | 65 |

| 4 | 2.5 | 0.8 | 4.2 | 4.9 | 0.21 | 1.4 | 11.7 | 13.7 | 273 | 5.09 | 110 | 55 |

| 6 | 3.0 | 0.9 | 4.9 | 5.7 | 0.21 | 1.4 | 13.1 | 15.4 | 351 | 3.39 | 90 | 45 |

| 10 | 3.9 | 1.1 | 6.1 | 7.1 | 0.21 | 1.5 | 15.7 | 18.5 | 515 | 1.95 | 85 | 45 |

| 16 | 5.0 | 1.1 | 7.5 | 8.8 | 0.26 | 1.5 | 18.1 | 21.2 | 710 | 1.24 | 70 | 35 |

| 25 | 6.4 | 1.3 | 8.9 | 10.3 | 0.26 | 1.7 | 21.8 | 25.6 | 1035 | 0.795 | 65 | 35 |

| 35 | 7.7 | 1.3 | 10.5 | 11.8 | 0.31 | 1.8 | 24.6 | 28.9 | 1339 | 0.565 | 60 | 30 |

| 50 | 9.2 | 1.5 | 11.9 | 13.8 | 0.31 | 1.9 | 28.4 | 33.3 | 1810 | 0.393 | 55 | 30 |

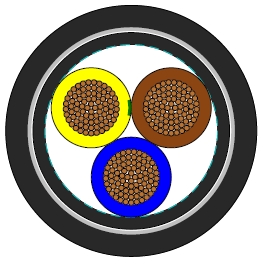

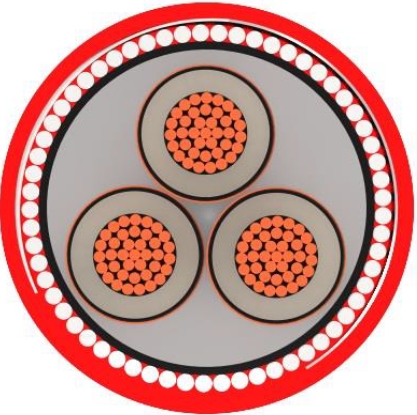

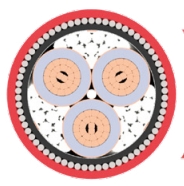

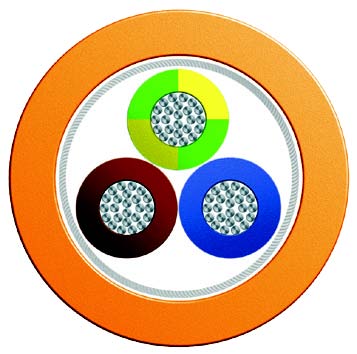

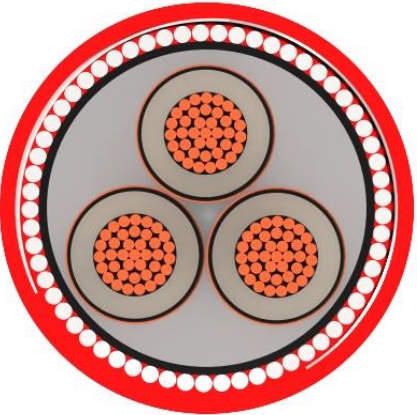

| THREE CORES | ||||||||||||

| 1.5 | 1.5 | 0.8 | 3.3 | 3.8 | 0.16 | 1.4 | 10.0 | 11.7 | 205 | 13.7 | 150 | 75 |

| 2.5 | 1.95 | 0.8 | 3.7 | 4.2 | 0.16 | 1.4 | 10.9 | 12.8 | 261 | 8.21 | 130 | 65 |

| 4 | 2.5 | 0.8 | 4.2 | 4.9 | 0.21 | 1.4 | 12.2 | 14.4 | 349 | 5.09 | 110 | 55 |

| 6 | 3.0 | 0.9 | 4.9 | 5.7 | 0.21 | 1.4 | 13.8 | 16.3 | 457 | 3.39 | 90 | 45 |

| 10 | 3.9 | 1.1 | 6.1 | 7.1 | 0.26 | 1.5 | 16.9 | 19.9 | 704 | 1.95 | 85 | 45 |

| 16 | 5.0 | 1.1 | 7.5 | 8.8 | 0.26 | 1.6 | 19.3 | 22.6 | 960 | 1.24 | 70 | 35 |

| 25 | 6.4 | 1.3 | 8.9 | 10.3 | 0.26 | 1.7 | 23.1 | 27.1 | 1400 | 0.795 | 65 | 35 |

| 35 | 7.7 | 1.3 | 10.5 | 11.8 | 0.31 | 1.8 | 26.2 | 30.8 | 1827 | 0.565 | 60 | 30 |

| 50 | 9.2 | 1.5 | 11.9 | 13.8 | 0.31 | 2.0 | 30.5 | 35.7 | 2513 | 0.393 | 55 | 30 |

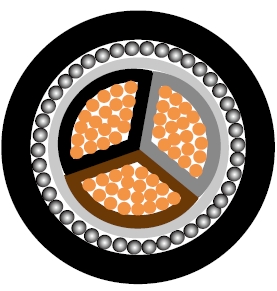

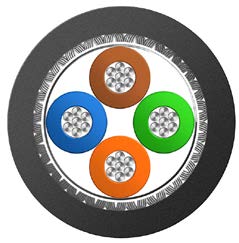

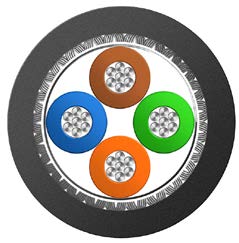

| FOUR CORES | ||||||||||||

| 1.5 | 1.5 | 0.8 | 3.3 | 3.8 | 0.16 | 1.4 | 10.7 | 12.6 | 248 | 13.7 | 150 | 75 |

| 2.5 | 1.95 | 0.8 | 3.7 | 4.2 | 0.21 | 1.4 | 12.0 | 14.2 | 335 | 8.21 | 130 | 65 |

| 4 | 2.5 | 0.8 | 4.2 | 4.9 | 0.21 | 1.4 | 13.3 | 15.6 | 430 | 5.09 | 110 | 55 |

| 6 | 3.0 | 0.9 | 4.9 | 5.7 | 0.21 | 1.4 | 15.1 | 17.7 | 570 | 3.39 | 90 | 45 |

| 10 | 3.9 | 1.1 | 6.1 | 7.1 | 0.26 | 1.6 | 18.6 | 21.9 | 896 | 1.95 | 85 | 45 |

| 16 | 5.0 | 1.1 | 7.5 | 8.8 | 0.26 | 1.7 | 21.3 | 24.9 | 1200 | 1.24 | 70 | 35 |

| 25 | 6.4 | 1.3 | 8.9 | 10.3 | 0.31 | 1.8 | 25.8 | 30.2 | 1815 | 0.795 | 65 | 35 |

| 3X35+25 | 7.7/6.4 | 1.3/1.3 | 10.5/8.9 | 11.8/10.3 | 0.31 | 1.9 | 30.2 | 35.4 | 2200 | 0.565/0.795 | 60 | 30 |

| 3X50+25 | 9.2/6.4 | 1.5/1.3 | 11.9/8.9 | 13.8/10.3 | 0.31 | 2.1 | 35.1 | 41.1 | 2600 | 0.393/0.795 | 55 | 30 |

(a) = for information, indicative only